I'm not sure if this should be classed as technology or nostalgia. When I first started working with computers I was fortunate to encounter CP/M systems and some early UNIX systems ... I never forgot how simple and efficient those systems were and how much you could accomplish with modest hardware. Entire companies running on multiuser systems with no more CPU power than an Intel 486 CPU (Does anyone remember those?)

In order to restrict the collection I've focused on systems that were available around 1975, they're the same age as me.

MITS - Altair 8800: "The Altair is widely recognized as the spark that ignited the microcomputer revolution as the first commercially successful personal computer."

More importantly it has blinking lights and switches on the front panel, lots of lights and switches!

Real computers let the operator halt the system and patch programs in binary then restart the system where it left off.

CP/M existed before MS-DOS and, if you've ever used DOS, you'll find that its eerily similar ... almost as it Bill Gates copied most of the concepts from other earlier operating systems.

In any case, CP/M has appeared in many different versions and even included multi-user variants. It ran on a large variety of hardware with different architectures and abilities. Code from one version of CP/M can be recompiled and ran on another.

I've enjoyed running favorite programs from my youth such as the original Infocom text adventures and programming in COBOL, FORTRAN and BASIC. You can even run simple programs programmed in binary on the front panel ... as long as you have the patience to toggle all those switches!

The picture to the right is my reproduction Altair 8800 system with DEC VT-220 monochrome serial display.

Digital Equipment Corporation - PDP 11/70: "The

PDP-11 is a series of 16-bit minicomputers sold by Digital Equipment Corperation (DEC) from 1970 into the 1990s, one of a set of products in the Programmed Data Processor

(PDP) series. In total, around 600,000 PDP-11s of all models were sold,

making it one of DEC's most successful product lines. The PDP-11 is

considered by some experts to be the most popular minicomputer."

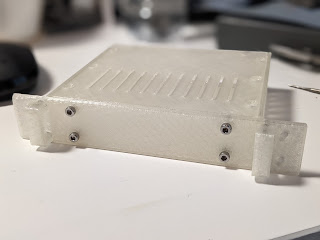

The reproduction system I have was supplied in a kit and powered by a Raspberry Pi. The assembly was fairly easy, the most time consuming part was installing and aligning the switches and LEDS. The result was rewarding as it exactly resembles a scaled down version of the PDP11/70 with all the peripherals emulated that were available for the systems. I've yet to set this system up in a permanent home but I have another DEC VT style terminal for it to connect to and a DEC LP-50 line printer to round out the installation.

The PDP11 system allows me to run classic operating systems from the time such as RSTS and RSX11M.

There are good development environments for FORTRAN and COBOL and DECs own variants of BASIC which are extended with additional function that hook into database like systems and external APIs.

It can run as a singer user system or multiuser and it was this latter mode that allowed the PDP systems to run in businesses and universities, serving many users at once while running physics simulations, word processing, teaching programming or running administration systems.